Glass cutting and grinding discs are typically ultra-thin, diamond-tipped blades for use with an angle grinder, suitable for both cutting and grinding various materials like glass, jade, and ceramics. They are designed for fast, clean cuts, can withstand wet or dry use, and minimize vibrations for straighter, smoother results. Safety precautions such as wearing goggles and gloves are essential when using these tools.

Key features

- Material: Made from high-quality diamond and a steel or high-manganese steel matrix for durability.

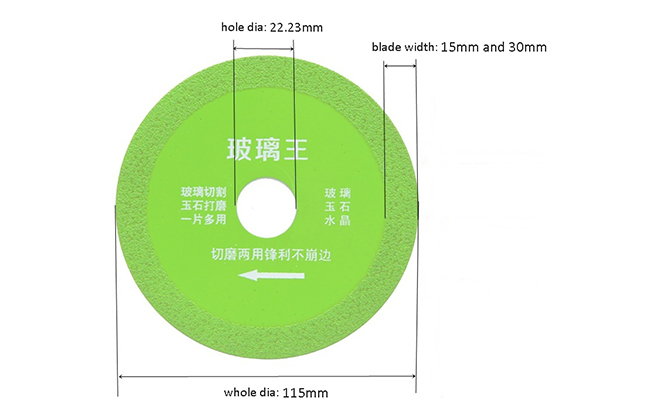

- Design: Ultra-thin, with a diameter of around 4 inches (10 cm) and a 7/8-inch arbor hole, often with a 1mm thickness.

- Performance: Designed for fast, clean cuts with minimal chipping, noise, dust, and debris.

- Versatility: Suitable for cutting, grinding, and chamfering glass, jade, crystal, ceramic, and wine bottles.

- Usage: Can be used for both wet and dry cutting, as well as for continuous use.

How to use

- Safety first: Always wear appropriate personal protective equipment (PPE), including safety goggles, gloves, and a mask.

- Mount the disc: Securely install the disc on an angle grinder, ensuring the speed does not exceed the manufacturer's recommendation (e.g., 12,000 RPM).

- Secure the workpiece: Clamp the material to prevent it from moving during the cutting or grinding process.

- Cut or grind: Use a steady hand to make consistent cuts. Apply steady, consistent pressure for uniform results.

- Cool down: Allow the disc to cool down periodically during prolonged use to prevent overheating.

- Alternative technique: For laminated glass, it can be helpful to cut partway through from one side, then finish the cut by coming in from the other side to avoid chipping the other face.