Door seals that combine brush and rubber components are hybrid products that leverage the strengths of both materials to provide effective sealing for various applications, especially the bottom of doors. The brush component is excellent for handling uneven surfaces, while the rubber provides a superior, airtight barrier against water and severe weather.

Materials and Construction

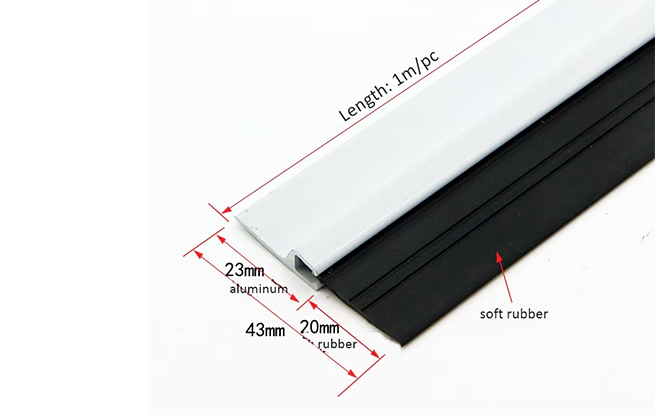

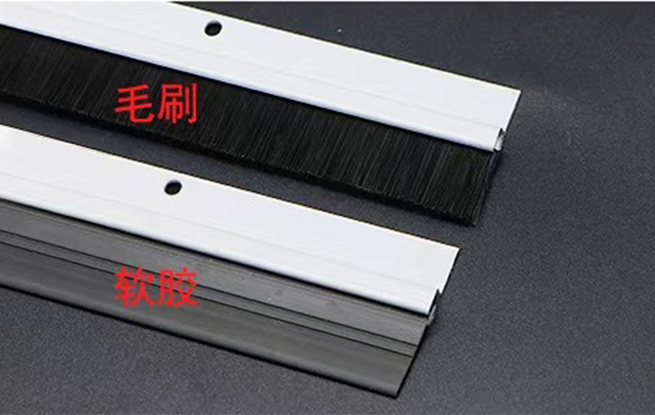

The seal typically consists of two main parts: the carrier (housing) and the sealing elements (brush and rubber).

- Carrier/Housing: This provides the structural strength and is commonly made from durable, corrosion-resistant materials like aluminum or stainless steel, or a more cost-effective option like PVC plastic.

- Brush Bristles: These are usually made of resilient synthetic fibers such as nylon or polypropylene. The bristles are flexible, durable, and designed to conform to irregular gaps without scratching the floor.

- Rubber Element: The rubber part is made from materials like EPDM (ethylene propylene diene monomer), TPE (thermoplastic elastomer), or silicone. These materials are chosen for their weather resistance and ability to form a tight, compressible seal.

Key Features and Benefits

This combination design offers a versatile solution with a range of advantages:

| Feature | Benefit | Best For |

|---|---|---|

| Dual-Action Sealing | The brush seals gaps on uneven floors, while the rubber provides a strong, weatherproof, and airtight barrier. | Dual-Action Sealing The brush seals gaps on uneven floors, while the rubber provides a strong, weatherproof, and airtight barrier. Exterior doors exposed to the elements or uneven thresholds. |

| Pest and Debris Control | The dense bristles act as a physical barrier to block out dust, dirt, insects, and rodents. | Garages, warehouses, or entryways in commercial/industrial settings. |

| Energy Efficiency | By minimizing air infiltration and drafts, the seal helps maintain consistent indoor temperatures, reducing heating and cooling costs. | Both residential and commercial applications where energy saving is a priority. |

| Noise Reduction | The materials help absorb and block sound waves, contributing to a quieter indoor environment. | Street-facing doors, home offices, or areas where acoustic insulation is desired. |

| Durability | High-quality materials like EPDM rubber and aluminum carriers ensure long-lasting performance, even with frequent use and exposure to harsh conditions. | High-traffic areas and exterior applications. |

Applications

Due to their hybrid functionality, these seals are highly versatile:

- Exterior Doors: They are ideal for exterior doors, where the rubber component is crucial for blocking rain and severe weather, and the brush helps seal gaps on uneven thresholds.

- Interior Doors: They can be used on interior doors to reduce noise transfer and prevent the spread of dust between rooms.

- Sliding Doors: The flexibility of the brush makes it well-suited for sliding doors where a compression seal might be difficult to achieve.

- Commercial/Industrial Settings: The robust construction (especially with metal carriers) makes them suitable for high-traffic commercial entrances or garage doors where durability is essential.